| Track span of the machine tool (mm) | HNC 2500G: Track span: 2500mm. Effective 2000mm HNC 3000G: Track span: 3000mm. Effective 2500mm

| |

| Track length of machine tool (mm) | 4000MM | 8000 |

| Effective cutting length max (change when add torch) | 3000mm | 7000mm |

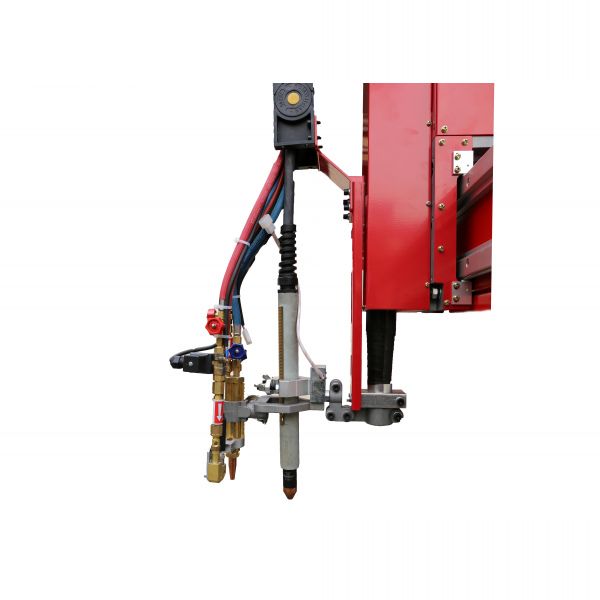

| Oxy-fuel torch | 1set | |

| Adjustor | 1set | |

| Auto ignition | 1set | |

| Plasma torch | 1set (togerther with Oxy-gas torch) | |

| AUTO HEIGHT CONTROL(THC) | 1set | |

| Add separated plasma or oxy-gas torch: | 1 set (can add plasma or oxy-gas lift): optional: add 810 usd | |

| PLASMA SOURCE | NO | |

| Cutting gas | Oxygen, acetylene/propane/air | |

| Transmission mode | Cross: Crawler-type; vertical: Chaining | |

| Driven approach | Double | |

| System controller | CCM3 | |

| Stepdriver | Change to Servo motor: add 1730 usd | |

| Relay | OMRON-Italy | |

| Nesting software | Sigmanest | |

| Stepping motor | 2H57M(China) | |

| Workbase(include the table middle) | NO | |

2.Technical index

Flame cutting thickness | 6-150mm | |

The elevation stroke of lifter(mm) | ≤200mm | |

Working Speed | 0-6000mm/min | |

Maximum air-way speed | 8000mm/min | |

Setting speed error | ≤±5% |

3. Requirement of working environment

1. | Power/frequency | 220v±10%/50Hz |

2. | Input power | 0.4KW |

3. | Oxygen pressure | 0.4-1.0MPa |

4. | Acetylene pressure | 0.05-0.1MPa |

5. | Temperature of working condition | 0-50℃ |

6. | Relative humidity | < 90%, non-condensation |

7. | The surrounding environment | Airy, no greatly impact |